Contact us for the latest range of professional Engine Driven Welder/Generators and consumables, or drop into our showroom at 500 Boundary St Toowoomba.

At Toowoomba Welding Supplies we keep a range of engine-driven welders and generators in stock, ready to go. However, generally we like to order custom-built machines so that the engine-driven welder or generator you buy will suit your specific application and situation.

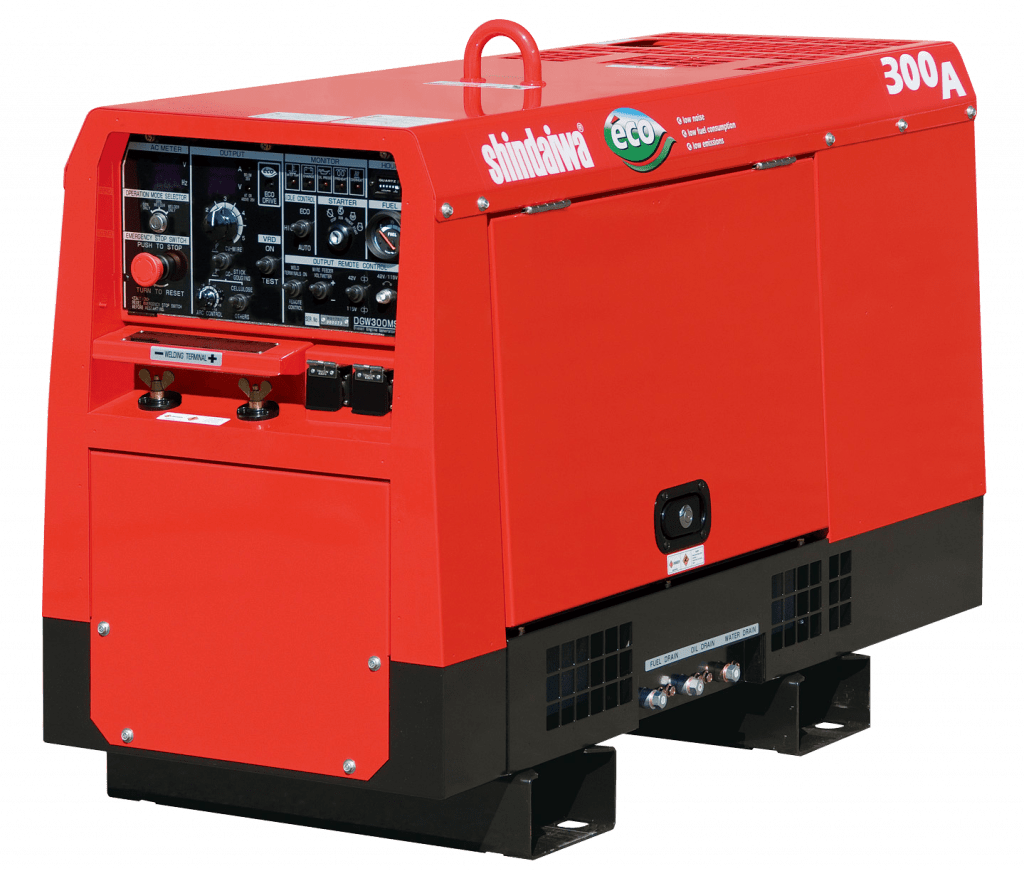

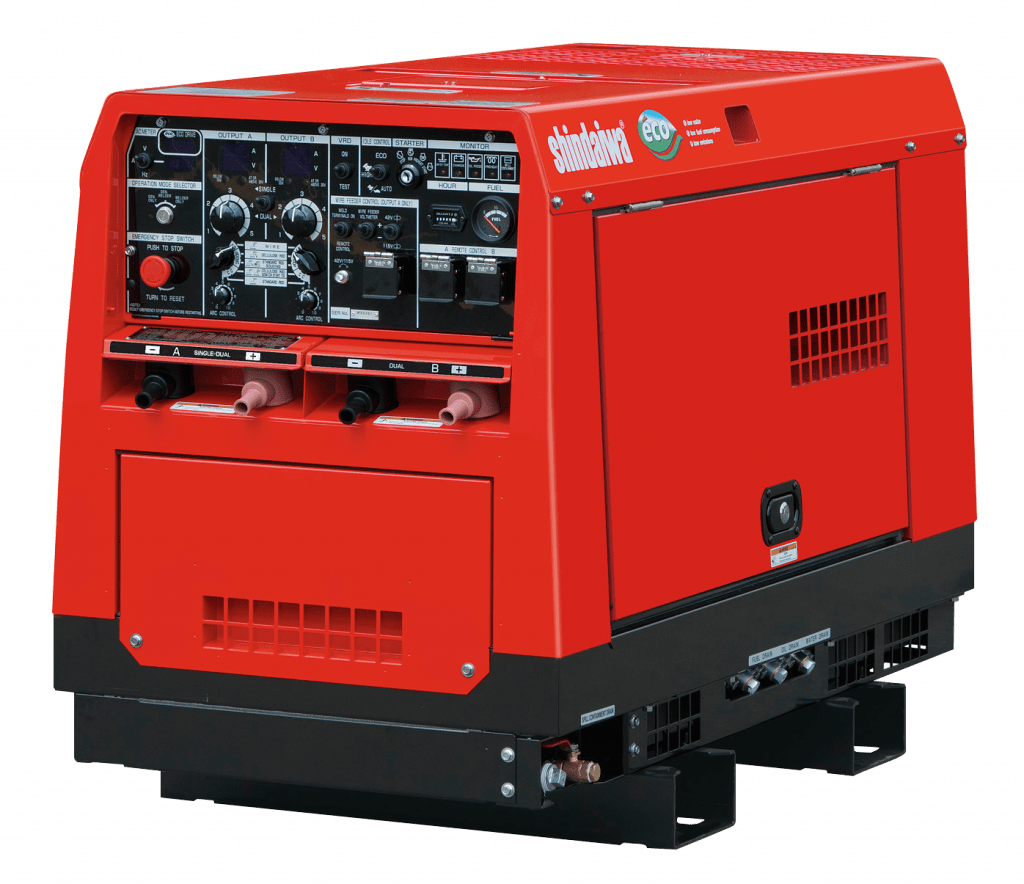

SHINDAIWA GENERATORS & WELDERS

Quality you can trust

Three key words identify and brand Shindaiwa in todays market place: Quality, Reliability and Performance.

- Designed and Manufactured in Japan with the latest technology.

- Manufactured to Australian standards and beyond..

- Real Dual Operator, Genuine 50hZ operation, VRD standard

- Built to last and perform in the tough Australian Conditions

- All Japanese Components giving strength and reliability.

- The quietest machines available in todays market place.

- Rigorous in House R&D testing is done for all the products we import and manufacture.

- Complete range of spare parts and service centers Australia Wide

Lincoln Outback

Top Features

Built for the Outdoors!™

Great for anyone who needs portable DC stick welding and AC generator power. The Low-Lift™ grab bars on both ends make lifting the Outback® 185 on and off truck beds easy. The compact Outback® 185 is easy to start with all engine controls on the front of the machine, and it’s easy to use for welding. Use the AC generator power for a variety of applications described below with the large 25.7 litre fuel tank! Plug in a Lincoln Electric POWER MIG® 180C for wire welding too.

Lincoln Dual Maverick® 450 (Perkins®)

Simple and Rugged.

Built for the construction site, pipeline and hire fleet. The Dual Maverick® 450

is two complete welders in one. The design features the 26.4 HP @ 3000 RPM

Perkins 403D-11 Tier 4i water cooled diesel engine. That is enough power for

two operators to weld at the same time, or for one operator to gouge with up

to a 8 mm carbon.

Lincoln Ranger 250

XTra Performance! XTra Power! XTra Protection!

Get all of the XTras needed for construction and maintenance work. That’s XTra welding performance with 250 amps for AC or DC stick and DC wire welding and XTra power with up to 7,200 watts continuous for lights, grinders or high amperage equipment. You also get XTra protection and quiet operation with the Lincoln enclosed case.

Lincoln Ranger 305D

Mine spec’d comes fitted with VRD, battery isolator and engine stop.

Excellent DC multi-process welding for general purpose stick, downhill pipe (stick), TIG, cored-wire, MIG and arc gouging.

Lincoln Electric Chopper Technology® provides easy starts, a smooth arc, low spatter and excellent bead appearance.

A portable powerhouse – delivers 7,200 continuous watts of 240V AC generator power. (2 x 240V 15A IP66 receptacles)

Arc force control – provides a soft or more forceful digging arc a built-in “hot” start for easier starts and restrikes.

Lincoln Vantage 400

Compact, Multi-Process, Excellent Value

The quiet, compact Vantage® 400 is an ideal choice for construction teams, pipe rig owners and rental fleet managers. Select your choice of proven 4 cylinder 1800 RPM diesel engines.

Compact Case with Stainless Steel Enclosure.

One of the most compact 400 amp machines available. Suitable for many pickup and service trucks.

Standard stainless steel roof, side panels and engine-access door deliver added protection and durability.

Lincoln Vantage 580

Get a 580 amp welder in a compact case. The same size as the Vantage® 400. A turbo-charged diesel engine with Lincoln Electric Chopper Technology® makes this a reality. Also, less weight than traditional 580 amp welders makes the Vantage® 580 compact design a great choice for installation on truck beds where available space and weight capacity are limited.

Lincoln Air Vantage 600

When the job calls for structural steel welding and other rugged outdoor work, you need an engine-driven welder that covers all your process needs – stick, MIG, TIG, flux-cored and gouging

– and also meets the latest diesel fuel emissions standards. Upgraded for Tier 4 Final (T4F)compliance, the Air Vantage 600 has been re-engineered to deliver smoother arc characteristics and improved pipe welding capabilities.

Choose the Air Vantage 600 for 575A/43VDC 100% duty cycle welding and gouging with up to10mm carbons. The Air Vantage 600 includes a belt-driven compressor with separate gauges to monitor compressor hours and pressure.

Miller Bobcat 260 Petrol

The industry’s most popular welder/generator is getting better. Building on its exceptional value, the new Bobcat is:

- Quieter to operate.

- Smaller and lighter.

- Easier to maintain.

Designed for Reliability

Miller welder/generators are the most rugged, durable and long-lasting in the industry. We manufacture them to exceed requirements for extreme working conditions

Miller Trailblazer 325

Trailblazer® welder/generators deliver unbeatable arc performance providing the smoothest, most stable arc in the industry. The Trailblazer exclusive technologies – Auto-Speed™ and optional Excel™ power – deliver superior runtimes, increased fuel efficiency, and improved welder/generator performance. No other compact machine in the 300-amp class delivers more welding power or more auxiliary power with better fuel efficiency and less noise — for productive, profitable, quieter jobsites.

Miller Big Blue 400X Pro

Designed with the professional in mind, the Big Blue 400 Pro is the best for ease of use, reliability and fuel economy.

Miller Big Blue 500X Pro

Clean, quiet, Multiprocess machine delivers up to 500 amps of welding power with an EPA Tier 4 Final engine, ideal for heavy use.

Miller Big Blue 800X Air Pak

The most powerful T4F diesel welder/generator/air compressor in the industry. The Big Blue 800 Duo Air Pak offers robust output for welding and power generation, and is ideal for dual-operator applications on labor intensive jobsites, or jobsites with limited space.

How to Select the Right Engine-Driven Welder

Engine-driven welders are generally used when electric power is not available for arc welding. Usually these are outdoor applications. However, engine-drive welders are often used for indoor applications when it is not convenient to supply power to electric “plug-in” arc welders.

These indoor situations include everything from minor repair jobs to major plant shutdowns. When operating engine-driven welders indoors, vent the exhaust outside if at all possible, or use in large spaces with good ventilation.

The basic considerations when choosing an engine-driven welder are:

Application

Engine Type

Portability

AC Generator Power

In trying to select an engine drive, the first thing to consider is the application. Ask yourself these questions:

Is this new construction or a repair job? Also, what is the size of the project?

Is there a particular welding process you would like to use? You may want to stick with a process with which you feel most comfortable, or there may be a certain process required on the job.

Is this a pipe welding project? The equipment chosen needs to produce an arc suitable for this type of work.

Will the job require arc gouging? Arc gouging is repair work usually done in industrial jobs.

What type of material needs to be welded? Most of the time the material will be a common mild steel plate. However, if it’s aluminum, the welding will require different equipment.

Using this information, match it to the welding processes described below.

Process Descriptions:

Stick Welding

CC (constant current) stick welding is the most common choice for field work. Electrode (welding rod) diameters most commonly used are 3/32″, 1/8″ and 5/32″. The simplest equipment will handle a wide variety of construction and repair applications. Output is measured in amps, and up to 200 amps is sufficient for the electrode sizes mentioned. Most equipment is DC (direct current) output for best arc stability. A 200-amp welder is usually able to get the job done.

Pipe Welding

Is most often done with stick electrodes. Look for equipment which specifies it will pipe weld, meaning that suitable arc characteristics are specifically provided for this process. Electrode diameters are typically 5/32″ and 3/16″, and 200 amps is sufficient for this process.

Arc Gouging

A process for removing metal. It is most commonly done in the stick mode. An arc is used with a carbon rod to melt metal and compressed air blows the molten metal away. Gouging is used to remove bad welds and to repair cracks. Most operators use equipment with 400 to 600 amps for higher productivity with 5/16″ or 3/8″ diameter carbon rods. However, smaller rods can be used with lower amperage. For example, a 5/32″ carbon rod can be used with 150 amps. Usually a separate compressor supplies the air. A few engine-driven welders are manufactured with built-in compressors.

Wire Welding

CV (constant voltage) wire welding requires a wire feeder. Wire welding’s main benefit is greater productivity: more weld metal can be deposited than for stick during the same amount of time. Although wire welding is much less common compared to the above processes, the application is growing. The engine-driven welder must have a CV-wire capability. Since most engine-driven welder work is outdoors, self-shielded flux-cored wire (which requires no shielding gas) is highly recommended to keep the process simple. When welding under windy conditions, the shielding gas associated with gas-shielded processes (solid wire or gas-shielded flux-cored wire) may be blown away, resulting in poor quality welds. Output is measured in volts and amps. Wire diameters are typically .035″ and .045″, although 5/64″ is often used for higher productivity. A welder with 30 volts and 300 amps is usually sufficient for many applications up to 5/64″ wire.

TIG Welding

A slower, but more precise type of welding well-suited for thin materials and unusual alloys. A TIG torch and shielding gas are required. If welding on aluminum, an AC weld output is required from the engine-driven welder and a high-frequency generator is attached to start and sustain the arc. Or, an AC TIG welder can often be powered from the engine-driven welder’s AC generator, if at least 8,000 watts is available. Most TIG welding is done below 100 amps.

Plasma Cutting

A metal cutting process which utilizes an arc and compressed air. The engine-driven welder’s AC generator can often supply power to a plasma cutter. At least 8,000 watts of power is recommended.

Engine Type

After the application has been defined and the welding process has been selected, the next step is to choose the engine. Diesel, gasoline or liquid propane gas (LPG) are the choices. A diesel engine offers better fuel economy than a gasoline engine, and diesel fuel does not ignite as easily as gasoline. Refineries almost always require diesel-fueled machines rather than gasoline-fueled machines. Another consideration for large jobs is whether the fuel is being supplied at the job site. If so, it is usually diesel, but whatever the fuel, the cost savings will usually determine the engine choice.

Gasoline engines are sometimes preferred in cold weather climates because they start more easily without extra starting aids, such as ether start kits and winterized fuel for colder weather.

LPG is much less common, but becomes an important alternative choice when diesel and gasoline exhaust emissions are not permitted for indoor applications.

A spark arrester may also be required in forest and oil service areas.

Portability

Sometimes the need for portability will be the main factor in equipment selection. If an engine-driven welder needs to be carried or lifted to a work area, having a small gasoline stick welder will normally be the best answer.

AC Generator Power

AC power is sometimes required on the jobsite for grinding welds, or for lights when working at night. Normally, 3,000 watts of AC generator power is plenty of power for these applications. Ground Fault Circuit Interrupters (GFCIs) are recommended and may be required. An AC TIG welder or plasma cutter will require more power – typically 8,000 watts minimum.