Contact us for the latest range of Internal Diameter (ID) welding equipment and consumables, or drop into our showroom at 500 Boundary St Toowoomba.

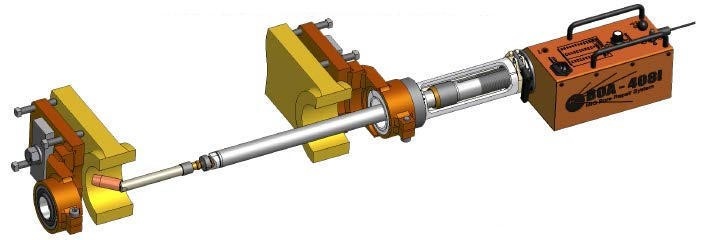

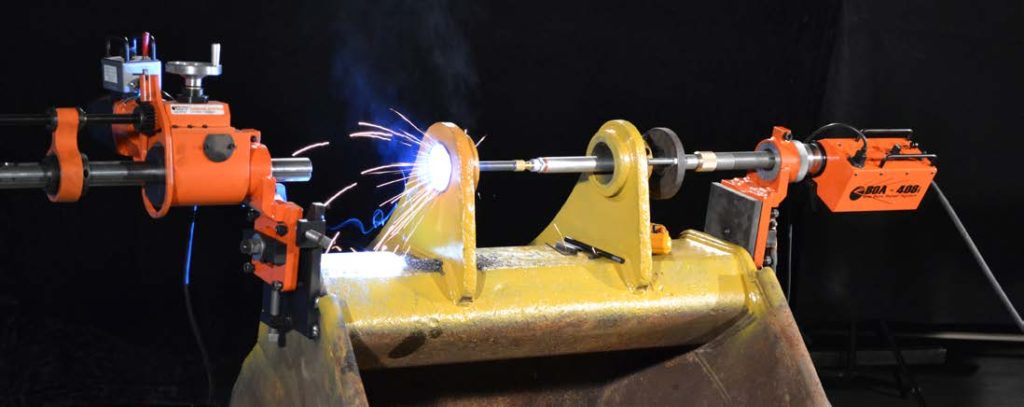

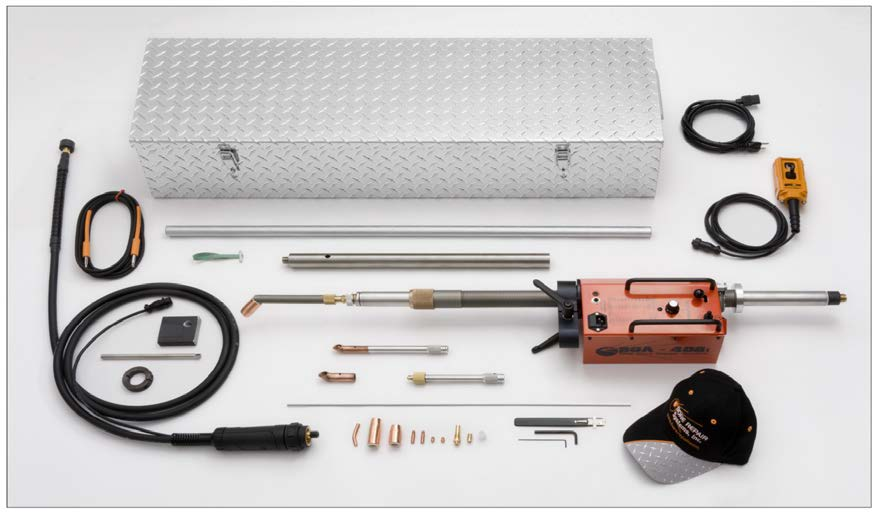

The BOA-408 Bore Welding System is the easiest to use & setup bore welding unit on the market.It will enable you to accurately & quickly weld bores and faces on any equipment in all axis.

The BOA-408’s patented quick release clutch makes positioning the torch extremely easy.

With a pass through main shaft and many different extensions & options you can use the modular BOA-408 to weld almost any size bore in any position.

You can use the same mounting fixture as the boring system if used in conjunction with a BRSEV series boring bar package.

BOA-408 S1 System Includes

- Main drive unit 240 volt

- Standard telescopic spindle with extension tube

- Standard conduit 3m (125 amp)

- Standard welding gun assembly (quick-connect) with spare nozzle and tip

- Microwelding gun assembly (quick-connect) for bores down to Ø20mm

- Axial torch extension 150mm (6”)

- 32mm (1.25″) stainless steel support tube with re-position groove

- Standard wear parts kit

- Arc start / stop / interrupt switch

- Tool kit & Operators manual

- Custom heavy duty aluminum carrying/storage case

BOA-408 S1 Specifications

- I.D. Weld Range-Ø20mm to Ø360mm(up to max Ø1220mm with options)

- Welding Current-125 amp (165 amp & 200 amp options available)

- Weight-11.4 Kg

- Feeding travel-178mmWire Ø-0.8 to 1.2mm (.03 to .045”)

Options

- Large diameter gun for inside diameters

Outside diameter welding gun - Extra large diameter beam gun welding kit for inside and outside diameters up to Ø1220mm

- Face welding torch kit that automatically feeds inwards or outwards up to Ø24”

- Axial torch extensions 150mm(6”) & 254mm (10”)

- Gun diameter extension adds 127mm (5”) to max diameter

- Adjustable “T” base for easy universal bore welder mounting and setup

- Heavy duty (165 amp) & extra heavy duty conduit (200 amp) for higher amperage welding

- Centering tube and cone kit for aligning unit to bore

- Auto skip upgrade & Boring Bar system

- Adaptor for mounting toEV boring bar bearing housing

BOA-408 S2 BORE WELDING SYSTEM

BOA-408 S2 Specifications

- I.D. Weld Range-Ø20mm to Ø533mm (up to max Ø1220mm with options)

- Welding Current-125 amp (165 amp & 200 amp options available)

- Weight-11.4 Kg

- Feeding travel-178mm Wire Ø-0.8 to 1.2mm (.03 to .045”)

BOA-408 S2 System Includes

- Main drive unit 240 volt

- Standard telescopic spindle with extension tube

- Standard conduit 3m (125 amp)with arc start / stop / interrupt switch

- Standard welding gun assembly (quick-connect) with spare nozzle and tip

- Large diameter gun (quick-connect)

- Micro welding gun assembly (quick-connect) for bores down to Ø20mm

- Axial torch extension 254mm (10”)

- 32mm (1.25″) stainless steel support tube with re-position groove

- Adjustable “T” base

- Standard wear parts kit

- Radial extension arm for large diameter reach

- Tool kit & Operators manual

- Custom heavy duty aluminum carrying/storage case

Options

- Outside diameter welding gun

- Extra large diameter beam gun welding kit for inside and outside diameters up to Ø1220mm

- Face welding torch kit that automatically feeds inwards or outwards up to Ø24”

- Axial torch extensions 150mm(6”) & 254mm (10”)

- Gun diameter extension adds 127mm (5”) to max diameter

- Heavy duty (165 amp) & extra heavy duty conduit (200 amp) for higher amperage welding

- Centering tube and cone kit for aligning unit to bore

- Auto skip upgrade & Boring Bar system

- Adaptor for mounting to EV boring bar bearing housing

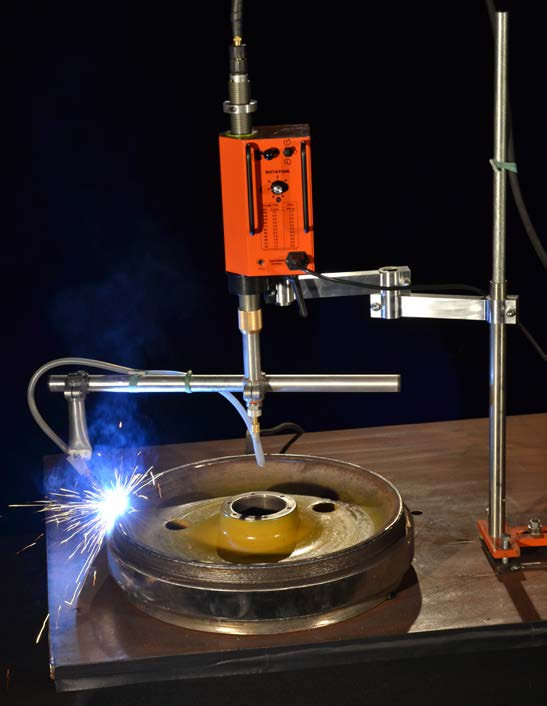

BOA-408 S3 BORE WELDING SYSTEM

BOA-408 S3 Specifications

- I.D. Weld Range-Ø20mm to Ø914mm (upto max Ø1220mm with options)

- O.D. Weld Range – Ø20mm to Ø305mm

- Face Welding Range – Ø20mm to Ø610mm

- Welding Current – 125 amp (165 amp & 200 amp options available)

- Weight-11.4 Kg

- Feeding travel-318mm

- Wire Ø-0.8 to 1.2mm (.03 to .045”)

BOA-408 S3 System Includes

- Main drive unit 240 volt

- Long stroke telescopic spindle with extension tube

- Standard conduit 3m (125 amp) with arc start / stop / interrupt switch

- Standard welding gun assembly (quick-connect) with spare nozzle and tip

- Large diameter gun (quick-connect)

- Micro welding gun assembly (quick-connect) for bores down to Ø20mm

- Outside diameter welding gun

- Face welding torch kit that automatically feeds inwards or outwards up to Ø24”

- 2 off gun diameter extensions, each adds 127mm (5”) to max diameter

- Axial torch extensions 150mm (6”) and 254mm (10”)

- 32mm (1.25″) stainless steel support tube with re-position groove

- Adjustable “T” base

- Standard wear parts kit

- 2 off radial extension arms 102mm (4”) & 203mm (8”) for large diameter reach

- Tool kit & Operators manual

- Custom heavy duty aluminum carrying/storage case

Options

- Extra large diameter beam gun welding kit for inside and outside diameters up to Ø1220mm

- Heavy duty (165 amp) & extra heavy duty conduit (200 amp) for higher amperage welding

- Centering tube and cone kit for aligning unit to bore

- Auto skip upgrade & Boring Bar system

- Adaptor for mounting to EV boring bar bearing housing

BOA-408 S4 BORE WELDING SYSTEM

BOA-408 S4 Specifications

- I.D. Weld Range – Ø20mm to Ø1220mm

- O.D. Weld Range – Ø20mm to Ø1220mm

- Face Welding Range – Ø20mm to Ø610mm

- Welding Current – 165 amp (200 amp option available)

- Weight – 11.4 Kg

- Feeding travel – 318mm Wire Ø-0.8 to 1.2mm (.03 to .045”)

BOA-408 S4 System Includes

- Main drive unit 240 volt

- Long stroke telescopic spindle with extension tube

- Heavy duty conduit 3m (165 amp) with arc start / stop / interrupt switch

- Standard welding gun assembly (quick-connect) with spare nozzle and tip

- Large diameter gun (quick-connect)

- Micro welding gun assembly (quick-connect) for bores down to Ø20mm

- Outside diameter welding gun

- Face welding torch kit that automatically feeds inwards or outwards up to Ø24”

- Extra large diameter beam gun welding kit for inside and outside diameters up to Ø1220mm

- Low speed kit for precision speed control when welding large diameters

- 2 off gun diameter extensions, each adds 127mm(5”) to max diameter

- Axial torch extensions 150mm (6”) and 254mm (10”)

- 32mm (1.25″) stainless steel support tube with re-position groove

- Adjustable “T” base

- Delux wear parts kit

- 2 off radial extension arms 102mm (4”) & 203mm (8”) for large diameter reach

- Tool kit & Operators manual

- Custom heavy duty aluminum carrying/storage case

Options

- Extra heavy duty conduit (200 amp) for higher amperage welding

- Centering tube and cone kit for aligning unit to bore

- Auto skip upgrade & Boring Bar system

- Adaptorfor mounting to EV boring bar bearing housing

Fronius TransSteel 2700 Compact

Single or 3 Phase

For guaranteed stable welding results, even at the power limit.

Proven to be an efficient power source for all Bore welding sytems

Easily converts from single phase to three phase

M1 Bore Welding System

The compact and lightweight M1 Bore Welding System is ideal for first time users and is a great value machine. Re-weld internal bores fast and easy with a manual drive system that is capable of welding ID’s up to 203mm. Save money by repairing your own equipment!

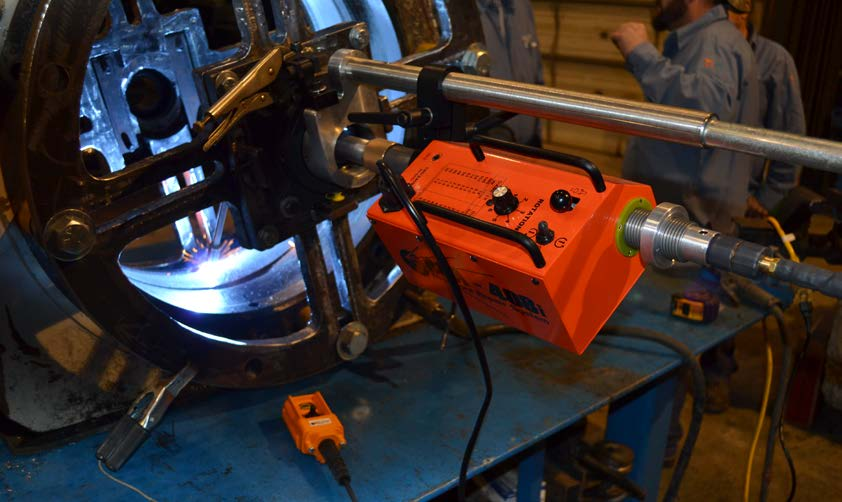

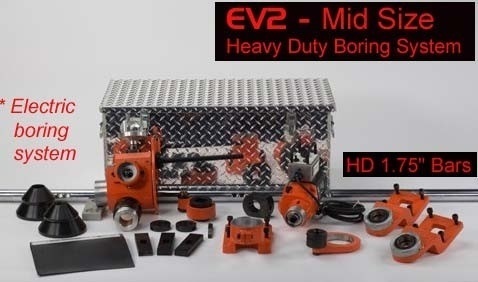

EV Series Boring Bar System

The EV Series Boring Bar System is ideal for repairing earth moving equipment as its bore machining range of Ø24mm to Ø254mm covers most bores that will be encountered doing these typesof repairs.

Its flexible boring bar pass through drive design is ideal for machining bores where there is restricted access or bores that are far apart.The pass through drive system gives you the flexibility to put the bearing mounts where it makes most sense such as between or outside the bores.

BOA C45 Line Bore Kit – For machining bore diameters up to 14” (356mm)

The Bore Repair Systems, Inc. BOA-C45 portable line boring systems are simple to use in the field and shop, rugged and extremely accurate. From the C45 precision hardened and chromed boring bars with staggered dual tool ports and morsetaper end to the unique external ratcheting, variable rate camfeed, tuneable ID bar support bearings and standard cone tightening system, the BOA-C45 line boring system will provide you with the features needed to quickly and accurately repair worn bores from under 1” to over 10” diameter on all types of equipment in a variety of industries. And while the BOA-C45 series line boring system features a powerful 3.3hp reversible, variable speed motor, the standard bar drive is a com-pact 15” wide* including the feedscrew. The C45 system also features the popular pass-through drive design allowing placement between bores, in tight-access spots, or to be used on tricky “blind bore” jobs or jobs where there are multiplebores in a line. The unique, dis-engagable feed arm allows simple tool repositioning without removing the tool from the bar….a feature not possible with old-fashioned traditional end-drive boring systems. Add one of Bore Repair’s automatic bore welding systems for maximum efficiency and productivity on all your bore repair jobs.