Contact us for the latest range of Thermic Lance Cutting Equipment and parts or drop into our showroom at 500 Boundary Street Toowoomba

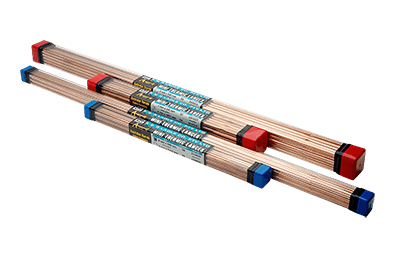

Mini Thermic Lance Range

Outside Diameter x Length

- 6mm x 505mm (1/4″ x 20″)

- 6mm x 1000mm (1/4″ x 39″)

- 10mm x 505mm (3/8″ x 20″)

- 10mm x 1000mm (3/8″ x 39″)

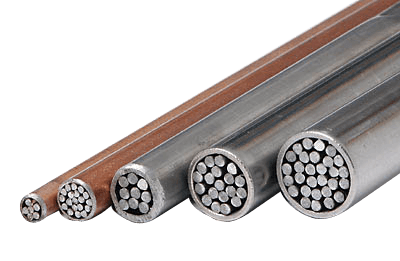

Thermic Lance Range

Outside Diameter x Length

- 12.70mm x 2.75m

- 16.00mm x 2.75m

- 17.40mm x 2.75m

- 19.00mm x 2.75m

- 21.50mm x 2.75m

- 26.90mm x 3.25m

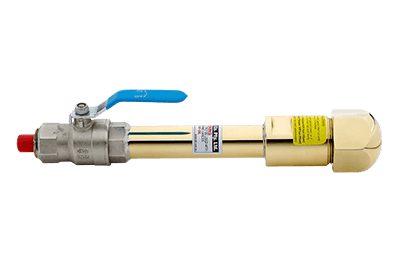

Thermic Lance Handle

A Thermic Lance Handle is necessary for the safe operation of a Thermic Lance. This Handle can be adapted to suit 12mm, 16mm & 19mm Thermic Lances. It has a built-in Flash/Slag Arrestor, which does not restrict the volume of Oxygen that is required to operate the Thermic Lance. The new design Handle now has a heavier Locking Nut to allow extra Hand-Tighten pressure on securing & sealing the Lance into position. Also, spanner grooves has been machined in, if the operator is fatigued and does not have to rely on Hand-Tightening alone.

This Handle should only be used with minimum 10mm I.D. Oxygen Hose with standard 5/8″ UNF Fittings

Recommended Operating Pressure : 420kpa (60psi) Do Not Exceed 600kpa (85psi)

If extra Oxygen Flash-Back Arrestors are used, please ensure they are High-Volume Arrestors, as the Thermic Lance requires sufficient volume to operate efficiently.

Mini Thermic Lance Kits

- New design Mini Thermic Lance Handle

- Handle to suit 6mm (1/4″) and 10mm (3/8″) Lances

- Lance Spatter Shield

- Oxygen hose (5m)

- Spare locking rubbers

- Y-Piece attachment

- Lance Igniter Tube & Wick

- Fume mask

- Thermic Lance Gloves

- Information and instruction sheets included

Other Accessories & Safety Apparel

- Aluminium Lined Leather Lance Jacket

- Aluminium Lined Full Leather Lance Trousers

- Leather Apron

- Proban Fire Resistant Hood

- Lance Face Shield – Shade 5

- Aluminium Lined Leather Lance Gloves

- Leather Spats for Boots

- P2 Rated Fume Mask

What is a Thermic Lance?

A Thermic Lance is a steel pipe packed with mixed metal wires. Pure oxygen gas is passed through the pipe from an oxygen cylinder and regulator. The end of the pipe is lit with a high temperature source, e.g. an oxy-acetylene torch. The iron in the steel burns in the oxygen coming down the pipe to produce enormous heat and a liquid slag of iron oxides and other materials, which dribbles and splashes out.

The temperature reached in the centre of the combustion zone is approx. 4000 degrees Celsius, greater than the melting point of any substance on earth. By the way of comparison, concrete melts at 1800 – 2500 degrees Celsius and steel at less than 1500 degrees Celsius.

A Thermic Lance is capable of cutting through :

- All ferrous and non-ferrous metals (recommended)

- Refractory materials such as linings and bricks (recommended)

- Underwater cutting of metal tracks, bridge supports (recommended)

- Concrete or rock structures (mainly for piercing holes only)

Common Applications

Cutting large metal castings or frozen metal spills

When foundries have large spillages of molten material, the only method to clean up is to use 16mm to 19mm Thermic Lances once material has solidified.

Cutting mixed or laminated materials

Combinations of metal and concrete are notoriously difficult to cut since the techniques for metal (drilling and oxy-cutting) are not compatible with those for concrete (drilling with tungsten carbide or diamond tipped tools and jack hammering). A lance will cut through both materials with ease at the same time.

Concrete cancer in reinforced concrete

A mini lance can be used to remove concrete cancer in coastal buildings and then re-packed with suitable new material.

Emergency situations

Widely used in emergency work around the world for disasters such as collapsed buildings due to earthquakes or train derailments etc.

Removing plugs, pins and hard-facing material

A Mini Thermic Lance is particularly effective when it comes to removing worn or seized pins in earthmoving equipment. It can also be used as a gouger to remove welds to replace teeth on buckets.

Furnace applications

Electric-arc and Blast furnaces have plugs which must be opened at regular intervals for inspection or draining purposes. Lances are also used for removal of worn refractory material and cleaning/de-slagging of pouring spouts.

General use

Cutting Large objects for scrap, cutting large steel beams in demolition and renovation, removing awkward objects from buildings (e.g. large statues, old bank vaults) and general maintenance applications.

For a Total Tools package, contact us on 07 46590044.