Contact us for the latest range of professional Line Boring, Internal Diameter welding equipment and consumables, or drop into our showroom at 500 Boundary St Toowoomba.

M1 Bore Welding System

The compact and lightweight M1 Bore Welding System is ideal for first time users and is a great value machine. Re-weld internal bores fast and easy with a manual drive system that is capable of welding ID’s up to 203mm. Save money by repairing your own equipment!

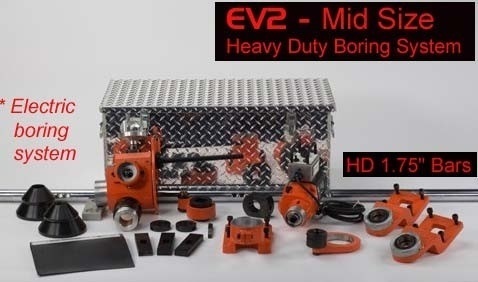

EV Series Boring Bar System

The EV Series Boring Bar System is ideal for repairing earth moving equipment as its bore machining range of Ø24mm to Ø254mm covers most bores that will be encountered doing these typesof repairs.

Its flexible boring bar pass through drive design is ideal for machining bores where there is restricted access or bores that are far apart.The pass through drive system gives you the flexibility to put the bearing mounts where it makes most sense such as between or outside the bores.

BOA C45 Line Bore Kit – For machining bore diameters up to 14” (356mm)

The Bore Repair Systems, Inc. BOA-C45 portable line boring systems are simple to use in the field and shop, rugged and extremely accurate. From the C45 precision hardened and chromed boring bars with staggered dual tool ports and morsetaper end to the unique external ratcheting, variable rate camfeed, tuneable ID bar support bearings and standard cone tightening system, the BOA-C45 line boring system will provide you with the features needed to quickly and accurately repair worn bores from under 1” to over 10” diameter on all types of equipment in a variety of industries. And while the BOA-C45 series line boring system features a powerful 3.3hp reversible, variable speed motor, the standard bar drive is a com-pact 15” wide* including the feedscrew. The C45 system also features the popular pass-through drive design allowing placement between bores, in tight-access spots, or to be used on tricky “blind bore” jobs or jobs where there are multiplebores in a line. The unique, dis-engagable feed arm allows simple tool repositioning without removing the tool from the bar….a feature not possible with old-fashioned traditional end-drive boring systems. Add one of Bore Repair’s automatic bore welding systems for maximum efficiency and productivity on all your bore repair jobs.