Contact us for the latest range of testing equipment and consumables or drop into our showroom at 500 Boundary Street, Toowoomba.

Weld Fillet Gauge

Weld Fillet Gauge Pro

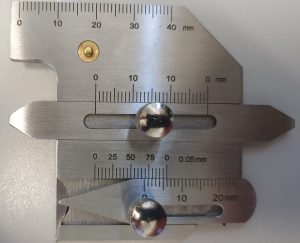

Digital Welding Gauge

DIGITAL Weld Measuring Gauge.

Eliminates rejects, improves productivity.

Small easy to carry, fit in most pockets, has own plastic case

Quick checking of pre-weld preparation bevelling, degrees on the blades

Measure welds professionally with a DIGITAL metric or imperial measurement tool.

Suit boiler makers and pressure vessel welders or tradesman.

PurgEye® 100 Weld Purge Monitor

Huntingdon Fusion Techniques HFT® is the first company to have developed a Weld Purge Monitor®.

The Company has continued to innovate year by year bringing to the market place a complete family range of weld purge monitoring instruments for other materials including duplex, nickel and cobalt steels, titanium, zirconium and other reactive alloys.

Hi-tech developments on the Argweld® PurgEye® 100 IP65 Weld Purge Monitor® include:

– IP65 dustproof and waterproof accredited

– Vacuum brazed leak tight probe assembly

– Push button “Auto Calibration” feature

– Low battery indicator and low sensor indicator

– Enlarged screen and large size digits

– Tripod mount (for fixed and gorilla tripods)

– Automatic sleep mode when not in use

– Leak tight quick connect/disconnect fittings for gas purge tubing

– Protective rubber cover (optional)

– More robust carry/presentation storage case

PurgEye® 500 Desk Monitor

The PurgEye® 500 Desk Weld Purge Monitor® has been specifically designed and developed by Huntingdon Fusion Techniques HFT® as a desk-based instrument that can be integrated with automatic welding equipment for consistent measurement and indication of oxygen levels.

The addition of PurgeNet™ allows the PurgEye® Desk Weld Purge Monitor® to control the welding process for precise measurements of oxygen levels to prevent welding in the event that the level is to high and to continue when the level is low enough, thereby creating zero colour welds every time.

The PurgeNet™ accessory allows control of automatic welding other accessories including visual on/off light for remote viewing, a dew point meter and a temperature monitor for interpass temperature control while purging.

This model is ideal for critical welds on materials such as stainless, duplex and chrome steels along with titanium, zirconium and nickel alloys. It can be used for joints made in Welding Chambers, Flexible Welding Enclosures® as well as for orbital welding applications and for use with Pipe Weld Purging Systems.

The PurgEye® 500 Desk Weld Purge Monitor® is perfect for ultra critical or ‘Golden’ welds, where oxygen levels need to be indicated to a very precise level as low as 10 ppm.

The PurgEye® 500 Desk Weld Purge Monitor® is particularly suitable for welds in ultra clean conditions, such as in the aerospace and cryogenics industries, food and drinks manufacturing, semi-conductor, pharmaceutical and petrochemical sectors as well as any other process industries.

The integral electro-mechanical pump is designed to extract samples from the purge volume at pre-determined user settable intervals to provide a consistent flow of exhaust purge gas over the sensor, for stable readings and equipment control.

PurgeLog™ Software allows the print out of Quality Management documentation where the recording and auditing capabilities are considered vital to the welding traceability.

PurgEye® 1000 Remote Weld Monitor

When welding joints in long tube line or pipeline sections, it may not be practical to measure the purge gas exhaust close to the weld.

Measuring purge gas exiting in the joint gap is also unsatisfactory because of the the oxygen being drawn in from outside and other variable factors.

HFT® has developed an answer to this difficulty, namely a sensing head that can be fitted onto the purging system, directly at the weld location and will measure oxygen level in the purge gas and transmit the information electronically to the remote monitor and operator that may be up to 1 km away.

In this way, the operator can be certain that the weld purge reading is correct and that the joint will not be adversely affected by oxidation.

Portable ‘handy’ Purge Monitor, reading from 1000 ppm down to 1 ppm (accurate to 10 ppm).

The PurgEye® 1000 Remote, now with PurgeNet™ is equipped with a stainless steel sensing head, which connects onto any Inflatable or mechanical Tube, Pipe and Pipeline Weld Purging System, producing accurate readings up to 1 km away from the weld.

The sensing head and the integral electro-mechanical pump are powered by the data cable, so only one cable is required. The sensor head is small enough to fit inside pipes from 1” (25 mm) diameter, upwards and is easily manoeuvred through pipes.