Contact us for the latest range of Lincoln Tig welders and consumables, or drop into our showroom at 500 Boundary St Toowoomba.

| INPUT POWER | 230/50/60 |

| RATED OUTPUT | 200A/18V@40%170A/16.8V@60% |

| INPUT CURRENT | 16A |

| OUTPUT RANGE | 6-200A |

| DIMENSIONS (H X W X D) | 380 mm x 215 mm x 480 mm |

| NET WEIGHT | 18 kg |

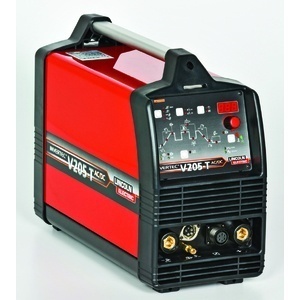

Lincoln Invertec V205-T AC/DC

Top Features

- Excellent arc characteristics for a wide range of applications.

- Generator compatible, ideal for site use.

- HF and Lift TIG ignition.

- Fully functional user-friendly control panel for easy setup of welding parameters.

- Fan as needed (F.A.N.™) built-in reduces power and the intake of dust and fumes.

Input Power

230/50/60

Processes

Stick, Lift TIG, TIG AC, TIG DC, TIG Pulse

Smart switching, full flexibility

The Invertec® V205-T PULSE is manufactured in a lightweight but robust outer casing, making it portable and ideal for operation, even in the most hazardous environments. The smart switching 230/400V single phase and generator compatibility of the V205-T PULSE allow it to be utilised anywhere on-site and in workshops. It features HF TIG ignition, Lift TIG ignition, 2 or 4 step, variable down slope and postflow control, a digital pre-set meter with a hold function and built-in variable pulse.

- Excellent arc characteristics for Rutile, Basic and Cellulosic electrodes up to 4.0mm

- Smart switching – 230/400V single phase.

- HF and Lift TIG ignition.

- Generator compatible ideal for site use.

- Fan as needed (F.A.N.™) – built-in reduces power and the intake of dust and fumes.

- High speed Pulse – to adjust the arc focus, reduce distortion and increase travel speed.

- Meets AS60974.1,AS60974.10,IEC60974-1,IEC60974-10, ROHS and CE – standards for safety and reliability.

| INPUT POWER | 230/400/3/50/60 |

| RATED OUTPUT | 300A/22V/35%200A/18V/100% |

| INPUT CURRENT | 32/20A |

| OUTPUT RANGE | 2-300A |

| DIMENSIONS (H X W X D) | 455 mm x 301 mm x 632 mm |

| NET WEIGHT | 43 kg |

Lincoln Aspect® 300

Top Features

- Advanced inverter technology for superior TIG performance.

- Superb welding characteristics with TIG DC, TIG AC and Stick welding processes.

- Adjustable cleaning and penetration for perfect aluminium welding.

- Variable AC frequency (40-400Hz) for control of travel speed and penetration.

- Full function user-friendly control panel layout with graph and a numeric display make it easy to set all welding parameters.

Input Power

230/400/3/50/60

Processes

Stick DC, Stick AC, TIG DC, TIG AC, TIG Lift, TIG HF, TIG Pulse

The TIG AC/DC new aspect!

Aspect® 300 is an industrial AC/DC TIG welding machine designed and manufactured using the latest inverter digital technology. This machine has been designed and built to perform in the most hazardous environments at high outputs: 300A at 35% duty cycle both in TIG AC and TIG DC application. The controller provides all the features you would expect from industrial AC/DC TIG inverter welding machines combined with a user-friendly front panel layout. Setting advanced TIG parameters has never been so simple! The top class features like the 2A minimum current, the multiple AC mode selection (including four different wave shapes), the optimized TIG start with adjustable electrode type and HF polarity, make the unit the right choice to suit any application. It can be simply changed to water-cooled by adding the COOL ARC® 46 Water Cooler. A robust, stable and well-equipped cart is available for easy movement of the unit.

- Advanced inverter technology for superior TIG performance.

- Superb welding characteristics with TIG AC, TIG DC and MMA processes.

- Adjustable cleaning and penetration for perfect aluminium welding

- Variable AC frequency (40-400Hz) for control of travel speed and penetration.

- Full function user-friendly control panel layout with graph and a numeric display make it easy to set all welding parameters.

- Rugged construction electrical safety (IP23), potted PC boards and optimum airflow reduce contamination to extend the equipments life in the harshest environmental conditions.

- PFC (Power Factor Correction) advantages 30% more output current with the same input current, suitable for 115-230V (+15%-10%) single phase, low current consumption, energy saving, low current harmonics and reduction of the total CO2 produced by the welding process.

- Water coolers and carts available.